How to choose crucible of induction melting furnace

Determination of crucible mould

The crucible of induction furnace is an important part of medium frequency furnace. It should have the function of high temperature resistance, insulation, heat insulation and energy conduction. It should have the ability of flushing resistance and compression resistance. In addition, it must also have electrical characteristics and stirring ability that does not affect the magnetic field. The size and depth of the mould determine the thickness of the furnace wall and bottom. If the mold is too large, the furnace wall will become thinner, the static pressure will increase with the capacity of the crucible, and the erosion force on the crucible wall will increase, which will affect the furnace life, but can improve the power factor. If the mold is too small, the furnace wall becomes thicker, the static pressure strength decreases with the capacity of the crucible, and the erosion force on the crucible wall decreases, which is conducive to prolonging the furnace life, but the resistance also increases, which reduces the power factor and increases the production cost. Therefore, it is very important to select the appropriate mold.

Selection of crucible burden

In addition to the required physical and chemical indexes, the smaller the charge expansion coefficient is, the better, so as to avoid the expansion crack caused by repeated temperature difference effect in use and affect the crucible life. According to the model of the equipment, the pH of the melting material and the temperature control during melting. At present, quartz sand and high bauxite are mostly used as masonry materials for intermediate frequency furnace crucibles in China. High bauxite material is suitable for medium frequency furnace below 500kg, dry quartz sand is suitable for crucible of induction furnace above 500kg, and quartz sand material for 2T smelting furnace is the most suitable. The quality of quartz sand material is mainly determined by the content of SiO2 and its particle size formula. The furnace life can be improved by changing the making of crucible. The acid crucible is made of acid oxide. The main oxide used for making acid crucible is SiO2. Almost all the acid crucibles are made of SiO2 based refractories, especially suitable for large induction furnaces with 5 ~ 30t capacity. Through the test, the expansion coefficient of the first kind of physical and chemical index of quartz sand is 7% ~ 9%, and that of the second kind is 0.5% ~ 2%.

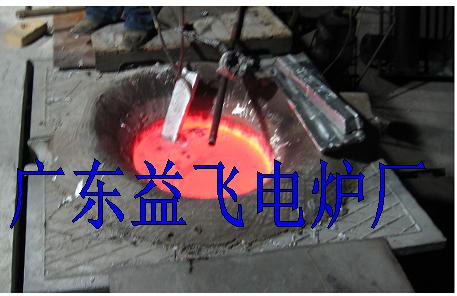

Yiphee Electric Furnace Co.,Ltd specializes in producing induction furnace.Tel(WhatsApp):+86-13450756789, yiphee@yiphee.cn

Modular induction furnace control cabinet

The melting speed of steel shell induction furnace produced by Yiphee is faster

Buy induction furnace, the first choice of 6-phase electrical input.

Why buy a series circuit induction melting furnace

Why choose to buy one drive two induction melting furnace?

What is one drive two induction furnace