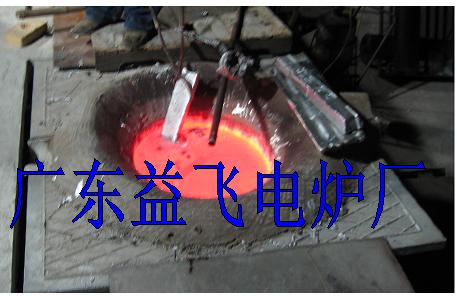

Aluminum melting in induction melting furnace

The electromagnetic stirring of induction melting furnace has the following advantages in aluminum processing and production: 1. It can make the alloy composition uniform. The electromagnetic stirring of induction furnace is sufficient and convenient, which can make the alloy composition of the whole furnace uniform within 10~20 minutes, avoiding the difference caused by different skills, physical strength and even labor attitudes of manual stirring. 2. Do not pollute the aluminum solution. Electromagnetic stirring is non-contact stirring, which has obvious technical advantages in the production of high-purity aluminum and strict control of harmful trace elements. 3. It can greatly shorten smelting time and reduce energy consumption. Due to the small aluminum blackness and low heat transfer efficiency, the implementation of electromagnetic stirring can accelerate the flow of molten liquid, greatly improve the thermal efficiency, shorten the smelting time by about 20%, and reduce the fuel consumption by about] 5%. 4. It can reduce the temperature difference between the upper and lower parts of the melt and reduce the generation of slag. Slag is an inevitable product in the aluminum smelting process, and its generation is related to many factors. When the melt temperature reaches or exceeds 750oC, the slag will increase sharply. The application of electromagnetic stirring can reduce the temperature difference between the upper and lower parts of the melt and the surface temperature of the melt. Generally, the slag can be reduced by about 20%. 6. It can reduce the labor intensity of workers, improve working conditions and improve labor efficiency. 7. It creates conditions for automation of aluminum melting and casting process.

Yiphee Electric Furnace Co.,Ltd specializes in producing induction furnace.Tel(WhatsApp):+86-13450756789, yiphee@yiphee.cn